Our team has worked to optimize current part packaging that composes the Jeep Wrangler. Through a detailed analysis of each part displayed on the manufacturing floor, we have achieved cost savings totaling $96,665, with additional savings anticipated as the project progresses.

Our approach involves identifying opportunities to increase packaging density, eliminate unnecessary partitions, and implement more efficient container solutions. Throughout this process, we collaborate closely with team leaders at the plant to ensure alignment and effective execution.

PACKAGING OPTIMIZATION

In compliance with Stellantis’s rigorous standards, our team developed steel racks that ensure exceptional protection for E-motor stator assemblies during handling and transport. The racks optimized part density without sacrificing safety, ensured compatibility with robotic systems, and adhered to all relevant safety and quality regulations.

This durable, reusable solution improved handling efficiency, streamlined operations, and offered a reliable, cost-effective packaging option that directly aligned with the client’s operational objectives.

RACKS

Our engineers developed custom injection-molded trays designed for the efficient and secure shipping of engine parts from various suppliers across the United States to Cummins Columbus Engine Plant in Indiana. The trays were engineered to support a hybrid handling process—allowing for manual or robotic loading at the supplier sites and robotic unloading at the destination facility.

This solution not only improved part protection during transit but also streamlined automation compatibility on the receiving end, enhancing overall operational efficiency and reducing handling errors.

CUMMINS

Flex’ approached us to help meet their packaging sustainability goals of material reduction, responsible sourcing, local production and reusability when appropriate. Our engineers modified the carton design for a cleaner look and created 69% more internal space, while maintaining the same blank size as current production design.

By changing their poly mailer from 2.5 mil to 1.5 mil thickness and reducing to only one size we simplified their process while combating material waste.

CONSUMER PACKAGING

Our goal is to create sustainable packaging by reducing material content and implementing 100% returnable systems when appropriate. Our engineers proposed changing from expendable partition assemblies in returnable bulk bins to returnable racks.

We compared reoccurring transportation and expendable dunnage costs and one-time purchases of returnable containers and racks. The implementation of a returnable rack system resulted in a 46% savings the first year. All following years resulted in an 83% savings.

SUSTAINABLE PACKAGING

Daily monitoring of returnable packaging throughout all Stellantis supply chain and programs using GPS trackers on packaging. Monitoring a few thousand active GPS trackers. There are short term and long-term benefits of keeping GPS trackers presence. Can immediately monitor the supply chain flow, and review system differences.

While long term we establish a presence in the supply chain that limits poor behavior and practices. This allows a reduction in expendable backup usage therefore driving down cost and any potential quality issues that may arise from an avoided repack. In 2024, Viacon recovered approx. $1.3M worth of excess containers at suppliers using GPS trackers.

GPS TRACKING

Coordinating trucking across the US, Canada, and Mexico. Providing dunnage for suppliers and plants, oftentimes relocating excess that was found through GPS tracking. Using the most cost effective freight solutions whether that be through LTL, milk runs, or alternative freight options.

TRANSPORTATION

Exciting News! We’re expanding! Our newest facility in Mexico is officially open, strengthening our global reach and enhancing our ability to serve clients with innovative packaging solutions.

Stay tuned for more details on how this expansion will bring greater efficiency, sustainability, and cutting-edge solutions to our partners.

MEXICO EXPANSION

Viacon Packaging Solutions partners with leading automotive manufacturers and other industries to engineer high-performance packaging solutions that ensure product protection and efficient logistics. Our expertise spans custom automotive packaging, impact-resistant designs, and sustainable material innovations, meeting the highest industry standards.

Beyond automotive, we tailor packaging for consumer packaging, electronics, industrial sectors, and battery components, delivering optimized solutions while also reducing costs.

LATEST

PROJECTS

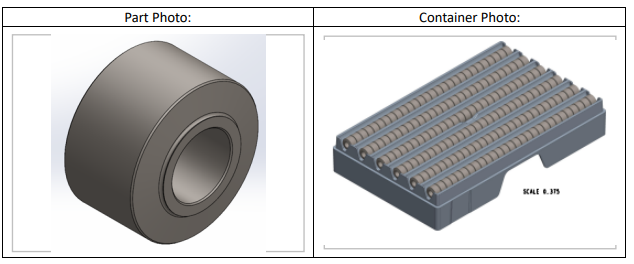

Our team has worked to optimize current part packaging that composes the Jeep Wrangler. Through a detailed analysis of each part displayed on the manufacturing floor, we have achieved cost savings totaling $96,665, with additional savings anticipated as the project progresses.

Our approach involves identifying opportunities to increase packaging density, eliminate unnecessary partitions, and implement more efficient container solutions. Throughout this process, we collaborate closely with team leaders at the plant to ensure alignment and effective execution.

PACKAGING OPTIMIZATION

In compliance with Stellantis’s rigorous standards, our team developed steel racks that ensure exceptional protection for E-motor stator assemblies during handling and transport. The racks optimized part density without sacrificing safety, ensured compatibility with robotic systems, and adhered to all relevant safety and quality regulations.

This durable, reusable solution improved handling efficiency, streamlined operations, and offered a reliable, cost-effective packaging option that directly aligned with the client’s operational objectives.

RACKS

Our goal is to create sustainable packaging by reducing material content and implementing 100% returnable systems when appropriate. Our engineers proposed changing from expendable partition assemblies in returnable bulk bins to returnable racks.

We compared reoccurring transportation and expendable dunnage costs and one-time purchases of returnable containers and racks. The implementation of a returnable rack system resulted in a 46% savings the first year. All following years resulted in an 83% savings.

SUSTAINABLE PACKAGING

Daily monitoring of returnable packaging throughout all Stellantis supply chain and programs using GPS trackers on packaging. Monitoring a few thousand active GPS trackers. There are short term and long-term benefits of keeping GPS trackers presence. Can immediately monitor the supply chain flow, and review system differences.

While long term we establish a presence in the supply chain that limits poor behavior and practices. This allows a reduction in expendable backup usage therefore driving down cost and any potential quality issues that may arise from an avoided repack. In 2024, Viacon recovered approx. $1.3M worth of excess containers at suppliers using GPS trackers.

GPS TRACKING

Viacon Packaging Solutions partners with leading automotive manufacturers and other industries to engineer high-performance packaging solutions that ensure product protection and efficient logistics. Our expertise spans custom automotive packaging, impact-resistant designs, and sustainable material innovations, meeting the highest industry standards.

Beyond automotive, we tailor packaging for consumer packaging, electronics, industrial sectors, and battery components, delivering optimized solutions while also reducing costs.

LATEST

PROJECTS

"Viacon’s precision packaging helped us reduce damage rates by 30%. Their expertise in automotive solutions is unmatched!"

Terry Cruise

Muscle Institute of America

"Reliable, innovative, and efficient—Viacon helped us transition to sustainable packaging without compromising performance."

Brad Pitt

Dream King Inc.

"Their custom solutions streamlined our logistics, saving us time and money."

Mark Cuban

Name Subtitle

Engineering Excellence in Packaging

Viacon Packaging Solutions is a leader in packaging engineering, serving consumer, automotive and emerging industries. Founded on innovation and precision, our solutions meet the highest standards of excellence.

We reduce environmental impact through material selection and reduced content.

Use this space to promote the business, its products or its services.

Vacuum Formed Trays

Use this space to promote the business, its products or its services.

Custom Dividers

Ideal for complex objects that need extra care

Injection Molding

Welcome to Our

New Mexico Facility

Exciting News! We’re expanding! Our newest facility in Mexico is officially open, strengthening our global reach and enhancing our ability to serve clients with innovative packaging solutions.

Stay tuned for more details on how this expansion will bring greater efficiency, sustainability, and cutting-edge solutions to our partners.

Contact Us

At Viacon Packaging Solutions, we specialize in engineering custom packaging that meets the unique demands of your industry. Whether you need durable automotive packaging, sustainable solutions, or high-performance protective materials, we’re here to help.

We value collaboration and are happy to discuss your needs in detail.